REGULATORY COMPLIANCE AND POWER PLANT ADVANCED CONTROL

Senergy CCI – Central Plant Controller

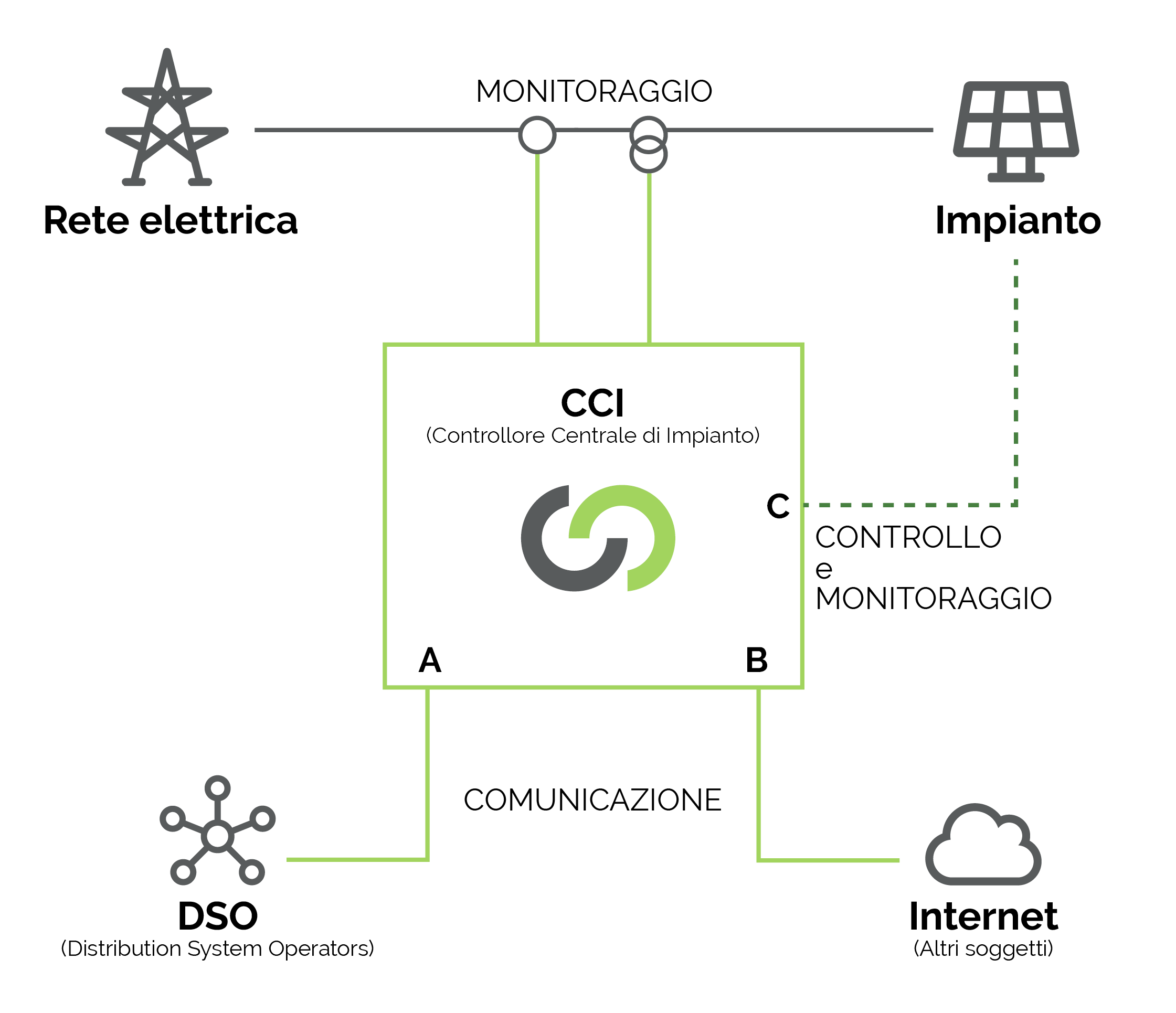

The Central Plant Controller (CCI) is a monitoring and control system installed at the point of delivery that allows DSOs to monitor and regulate the generation plant, enabling it to participate in grid balancing.

The CCI was introduced in Italy in 2022 with the V1 and V2 variants of the CEI 0-16 standard. The key requirements requested by the regulation include the PF1 (Monitoring), PF2 (Regulation and Control), and PF3 (Participation in Flexibility Markets and Plant Optimization) functions, which are essential to ensuring the security and stability of the national electricity system.

The Senergy CCI Higeco More solution is designed to fully meet all technical requirements, offering all the functionalities (PF1, PF2 and PF3) in a single device, with maximum reliability and ease of integration.

PF1, PF2 e PF3 features

Certified CEI 0-16

Cybersecurity

SENERGY CCI – CENTRAL PLANT CONTROLLER

Features and functionality

DOWNLOADS

Download all documents

CCI Higeco More Certifications

Consult the copy of all the CCI Higeco More certifications required by the CEI 0-16 standard

Brochure CCI

Learn more about all the technical details and more of the Higeco More Central Plant Controller (CCI) solution

HIGECO MORE ANSWERS THE MOST COMMON QUESTIONS ABOUT CCI

FAQ on the Central Plant Controller (CCI)

Updated to ARERA Resolution 564/2025/R/EEL, December 23, 2025

In this section, we’ve collected the most frequently asked questions about the CCI, which emerged during the

dedicated webinar and other discussions with our customers. Here, you’ll find practical answers and regulatory references to clarify doubts and learn more about the operation of the Central Plant Controller.

Resolution 385/25/R/eel, and the subsequent 564/25/R/eel, positively verify revision 2 of Annex A72 to Terna’s Grid Code and consequently extend the scope of application of the CCI to photovoltaic and wind plants with a nominal power greater than or equal to 100kW, always connected to MT.

Plants with a nominal power greater than or equal to 100kW and less than 500kW are considered EXISTING if they were already connected to the grid on the date of publication of the resolution (August 6, 2025) or if they submitted a connection request before October 31, 2025.

Both plants with a nominal power greater than or equal to 500kW and less than 1MW, and those with a nominal power greater than 1MW, will be considered EXISTING if they were already connected to the grid on the date of publication of the resolution (August 6, 2025) or if they had already submitted a connection request before that date.

Power plants not included in the above definitions are considered NEW.

For EXISTING systems, the Resolution requires ADAPTATION, i.e. installation of the CCI, if not already present, and activation of the PF2 function for limiting Active Power upon external command from the DSO, within the deadlines indicated above.

For NEW systems, the Resolution requires the installation of the CCI and the activation of the PF2 function for limiting Active Power upon external command from the DSO, by the time of connection to the grid.

For power plants with a nominal power greater than or equal to 1 MW connected to medium voltage, the obligation remains valid for all technologies, without distinction.

For power plants with a nominal power less than 1 MW, also connected to medium voltage, the obligation applies only to photovoltaic and wind technologies.

In the future, it will likely be extended to other technologies as well, and ARERA will define the modalities with a dedicated resolution.

If the system has a nominal power greater than or equal to 100kW, this is correct, as Resolution 385/25 extends the requirement for photovoltaic systems up to 100kW.

If, however, the system has a lower nominal power, it could be an error due to incorrect or outdated data on Gaudì. You can report this to the DSO by replying to the certified email received.

Resolution 385/25/R/eel, and the subsequent 564/25/R/eel, establish the provision of a bonus for the adaptation of existing plants, but only those with a nominal power of less than 1 MW.

Existing systems with a nominal power of 100kW or more but less than 500kW will receive a financial contribution of:

– €7,500 if they submit the Compliance Declaration by January 31, 2027

– €6,000 if they submit the Compliance Declaration by March 31, 2027

– €3,000 if they submit the Compliance Declaration by June 30, 2027

– No financial bonus if they submit the Compliance Declaration after June 30, 2027 and before the mandatory deadline, i.e., March 31, 2028.

Existing plants with a nominal power greater than or equal to 500kW and less than 1MW will receive a financial contribution of:

– €1,000 if they submit the Compliance Declaration by December 31, 2026

– €8,000 if they submit the Compliance Declaration by February 28, 2027

– €4,000 if they submit the Compliance Declaration by May 31, 2027

– No financial bonus if they submit the Compliance Declaration after May 31, 2027 and before the mandatory deadline, i.e., December 31, 2027.

Revision 4 of CEI 0-16, published in 2025, eliminated Annexes K and X, referring directly to the Terna Grid Code for HV-connected systems: Annex A68 for photovoltaic systems, A79 for storage systems, and A17 for wind systems. For MV-connected systems with a power greater than 6 MW, the same requirements apply as for smaller MV-connected systems.

Yes. The scope of application is defined based on the nominal power of the system, calculated as defined by the CEI 0-16 standard, not on the maximum grid feed-in power.

Specifically, for photovoltaic systems, the nominal power must be calculated as the sum of the lower of the AC and DC power of each inverter.

Yes, in the transitional phase, that is from the publication of the Resolution until the deadlines indicated for the definition of existing plants, it is necessary to install both.

In general, for existing systems, it is necessary for the remote disconnection modem to remain functional until the completion of the upgrade, in particular until the functional checks of the DSO have been passed.

Yes, as indicated in the TIDE, but only for the portion of energy sold. Any incentive will not be reimbursed, as it is allocated to the energy PRODUCED, which in this case was not generated.

Yes, it is. For hybrid systems, i.e., systems with multiple technologies, the definition of a system in the TICA is considered for applicability: a system is defined as a group of generators, of the same technology, connected under the same POD.

The CCI is mandatory if under a MT POD there is at least one system with a nominal power greater than or equal to 1MW, or if there is a photovoltaic or wind system with a nominal power greater than or equal to 100kW. In this second case, the PF2 Active Power Limitation function must also be activated upon external command from the DSO.

Yes, to be compliant with CEI 0-16, the CCI must have all the functionalities defined in Annexes O and T: the functional performances PF1, relating to observability, PF2, relating to controllability by the DSO, and PF3, relating to controllability by the aggregator/bsp.

Arera Resolutions 540/21 and 385/25 establish whether or not the activation of various functions on systems is mandatory.

Resolution 385/25 establishes the mandatory activation of the PF2 Active Power Limitation function upon external command from the DSO for photovoltaic and wind systems connected to medium voltage with a nominal power greater than or equal to 100 kW.

Yes, in addition to the PF2 Active Power Limitation function upon external DSO command, which must be activated on all MV-connected photovoltaic and wind power systems with a nominal power greater than or equal to 100kW, when defining the Operating Regulations, the DSO can request the activation of other specific PF2 functions. The Producer can always refuse, but these functions are not mandatory.

No, it remains invalid as previously.

Annexes O and T state that the time synchronization function can be performed by a GPS receiver integrated into the CCI, or it can be provided via a local communications network service, using the NTS protocol, the secure version of NTP.

The DSO, as required by Resolution 540/21.

The battery limit, between the DSO’s scope of supply and that of the Manufacturer, is the optical cassette that the DSO installs in the measurement compartment of the Secondary (exchange) cabin.

It better be. In fact, the CCI must use a PKI (Public Key Infrastructure) for the management of security certificates (See CEI 0-16 T.3.3.4.9). According to Annex T there are 3 ways to do it:

1 – Manual Management (temporary solution only): Installations, updates, revocations, replacements, of DSO certificates and any BSPs must be done manually on each plant. Challenging and error-prone if there are many CCIs to manage.

2 – Local PKI in the plant and OCSP protocol: Installing and managing a local PKI is very expensive and difficult. It is neither convenient nor secure.

3 – External PKI in CLOUD: The CCI uses an external PKI in #cloud, through the internet connection. Secure, centralized and automatic management of the certificate life cycle.

In addition, a CCI connected to the internet is easier to update – mandatory updates are already planned in the coming years – to reach and consult – through our portal – to replace in case of failure – automatic backup of configurations and data.

The data to be collected by the CCI remains essentially unchanged from the past.

For Delivery Points, the CCI must directly measure P, Q, V, and optionally I, and acquire the status of the DG and DI.

For Single Generators, the CCI must acquire the P measurement and the status of the DDG (or equivalent).

Individual generator data is required only for new systems with a power output greater than or equal to 1 MW, and only if the generators have a nominal power greater than:

– 170kW for static converters (e.g., photovoltaic inverters)

– 250kW for traditional generators

– 50kW for storage

Furthermore, among the simplifications introduced by the CEI for power plants with a nominal power of less than 500 kW, it is established that:

– for fully sold and single-source plants only, the aggregate generated power can be assimilated to the power fed into the grid, measuring only the latter.

– the maximum allowable error for measurements increases from 2.2% to 5%.

The CEI 0-16 standard requires that MV measurements must be taken at the point of delivery directly by the CCI using its measurement unit.

The standard recommends using a Class 0.2 or better Measurement Converter and Class 0.5 or better CTs and VTs, with a rating of 5 VA or 10 VA. The CTs and VTs can be shared with other systems, excluding the fiscal measurement group, without creating interference.

Measurement systems with different characteristics are also acceptable, provided they comply with the accuracy required by Annex A.6 of the Terna Network Code, table 5: maximum error in the measurement of P, Q and V less than 2.2%, which increases to 5% for systems with nominal power less than 500kW.

The CEI 0-16 standard specifies that the measurements and statuses of individual generators, and the measurements of the aggregate generated power, can also be acquired by the CCI via communication with other system elements, using standard communication protocols, provided that the required accuracy is guaranteed.

For delivery point measurements, however, the law establishes that they be acquired directly from the CCI.

No, because the protectors use protective CTs, which cannot guarantee the required accuracy.

As indicated in paragraph O.14 and in figures O.1 and O.7 of CEI-016 2025-04, monitoring of the status of the DG and all the DIs is required, through direct acquisition (clean contact) or by communicating with other system elements (e.g. SPI).

Yes, as indicated in the interpretative note published by the CEI in July 2023.

Resolution 540/21/R/el establishes that DSOs that do not intend to carry out data collection and regulation activities may use a third-party distributor, “such as, for example, the reference distribution companies or, in the case of SDC, the concessionary distribution companies in the territory in which they operate“. Alternatively, the DSO could submit a communication of motivated renunciation to Terna by 31 January 2022, which will evaluate alternative solutions. Ultimately, Terna will carry out the data collection directly, via the IEC 60870-104 protocol.

Yes, CTs are not the only measurement system available. You can also use Rogowski probes, but be careful because they are not as precise as CTs, and the CEI 0-16 standard requires that a total measurement error on P and Q be guaranteed to be less than 2.2%!

If you choose CTs measuring in class 0.5, as indicated in CEI 0-16, you will be able to avoid additional tests and compliance problems.

Yes. The CEI 0-16 standard establishes that the TVs for measuring the Minimum Homopolar Voltage must always be installed in MV at the connection point, and can be equipped with a double secondary (one for protection and one for measurement), or a single secondary with a double class (protection and measurement).

In the first case, the CCI can be connected to the measurement windings, even in parallel with other systems already connected.

In the second case, the CCI can be connected to the secondaries already connected in open delta to the Interface Protection, creating a separate connection to each VT. This way, it is always possible to take the three Phase-Earth voltages, without interfering with the measurement of the Minimum Homopolar Voltage.

In any case, the requirement regarding the maximum measurement error must always be respected, which must be less than 2.2%, or 5% only for systems with a nominal power of less than 500kW.

Yes, the status of the GSM modem for remote disconnection is one of the signals that the CCI is required to acquire mandatorily. Although it is not included in the observability dataset, it is among the signals required by Chapter 14 of Annex O (“Data Logger”). The intervention signal must be acquired during the transitional phase, in which the modem must remain operational, until the completion of the verification process with the DSO concerning the CCI and the active power limitation function via external command (Rigedi).

Key points for correct management:

Modem removal: Monitoring of this component remains necessary until the modem can be removed. Such removal is subject to the completion of the verifications carried out by the DSO (Distribution System Operator) regarding the effective operability of the CCI with the Active Power Limitation function PF2 enabled.

Regulatory requirement: According to the current A72 Rev.2 and Resolution 385/25, the CCI is required to monitor the intervention of the remote disconnection modem (Annex M).

Acquisition method: The modem status can be acquired via digital contacts or through a communication protocol, either directly from the modem itself or from the interface protection device.

The CCI control functions are based on closed-loop regulators, which read the measurements at the delivery point, compare them with the set points, received (servo mode) or calculated (autonomous mode), calculate the set points to be sent to the generators/converters and send them. Consequently, the CCI must be able to communicate reliably and quickly with the generators/converters, which must implement a standard communication interface and protocol that includes the possibility of receiving commands in P and Q (or equivalent, for example PF or PHI). If the communication is based on serial protocols, such as RS485 or CANBUS, and not Ethernet, it is more difficult to respect the prescribed response times, and it is necessary to evaluate the feasibility on a case-by-case basis.

Many photovoltaic inverter models, even older ones, are already designed to be controlled by an external control system, meaning they support receiving commands via standard communication protocols to regulate active and reactive power. Sometimes, it may be necessary to update the inverter’s firmware, or install an additional internal card or external data logger.

In the case of the active power limitation function, if the inverters cannot be regulated at all, the CCI can implement the command by disconnecting the individual inverters, i.e. by partially reducing production, while still keeping the system connected to the grid, i.e. by keeping the DI and DG closed.

Similar to photovoltaic inverters, traditional generators can also be regulated by sending active and reactive power commands, directly or through an external controller (e.g., PLC).

Even for traditional generators, in the case of the active power limitation function, if the generators cannot be regulated at all, the CCI can implement the command by disconnecting the individual generators, i.e., partially reducing production, while still keeping the system connected to the grid, i.e., by keeping the DI and DG closed.

Yes. Annex O of the CEI 0-16 standard does not impose requirements on how the CCI is connected to generators/inverters.

In any case, the connection must ensure compliance with the standard’s requirements, in particular:

- Reliability: The CCI, and some of its features, must be available 99% of the time annually.

- Performance: the CCI must be able to collect data from individual generators, if requested, with a maximum sampling time of 4 seconds, and the response time of the control functions must be less than 1 minute for active power regulation, including Active Power Limitation upon external command from the DSO (required by Resolution 385/25), and 10 seconds for reactive power regulation.

Once all tests, including functional tests, have been performed and the certifications described in Chapter O.15 of CEI 0-16 2022-03 have been obtained, CCI manufacturers may issue a self-declaration of conformity to the standard, Annexes O and T. The resulting technical file must be retained for at least 10 years from the product’s last manufacturing date and must be made available to the regulatory authorities. A third-party body accredited for these annexes of the standard can certify the product’s conformity, further supporting the self-declaration.

Chapter O.15 of CEI 0-16 2022-03 specifies stringent requirements for both hardware and software cyber security. In particular, the use of a cryptographic component capable of detecting and responding to physical tampering is required, certified according to FIPS-140-2 with level 3. Furthermore, certification to IEC 62443-4-1 is required, according to the IsaSecure Secure Development Lifecycle Assessment (SDLA) scheme, of the CCI production process, and to IEC 62443-4-2, according to the IsaSecure Component Security Assurance (CSA) scheme, of the CCI product.

Chapter O.15 of CEI 0-16 2022-03 requires that the CCI be IEC 62443-4-2 certified according to the IsaSecure CSA scheme (which includes and exceeds the EDSA cited in the standard). This certification requires numerous IT security features, which must be implemented, and tested, by the CCI. Annex O of CEI 0-16 2022-03 establishes that all the required CCI features “…they can also be integrated into one of the other devices constituting the system provided that it is possible to test the features of the aforementioned devices according to the indications of this Annex”. In summary, the features must be present, in integrated form or not, in the CCI, and these must be tested and certified.

No, the CEI 0-16 Annex O standard requires several tests, which cannot be carried out in just any laboratory. To comply with the standard, the product must pass the insulation, EMC, noise immunity and climate tests in an ISO 17025 accredited laboratory, and the functional tests in the presence of an ISO 17065 accredited inspection body.

Once all the tests have been passed, the relevant test and inspection reports have been obtained, and the required certifications have been obtained, at that point the manufacturer self-declares that the CCI complies with CEI 0-16 Annex O and T. The technical file with all the test reports and certifications must be kept and made available for 10 years.

Want to know more about the CCI?

Contact us for more information on the Central Plant Controller and the ARERA Resolution.